Working area flat cutting table cutting no collector table stepper motor providing 1 meter of space on each side of the cutting area is enough to operate the cnc plasma cutting machine.

Plasma cutting machine working principle pdf.

The temperature of the plasma is in excess of 20 000 c and the velocity.

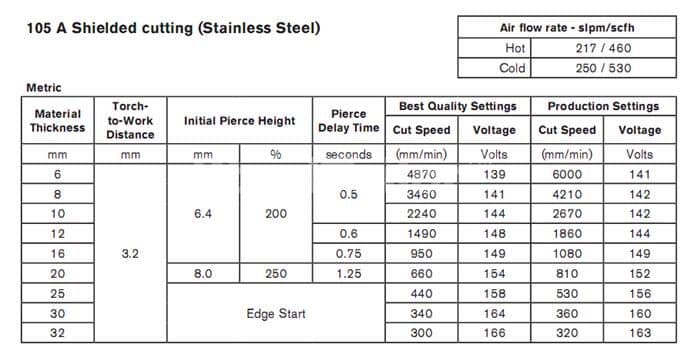

Plasma arc cutting machine with automatic torch travel was used to cut ss304 work.

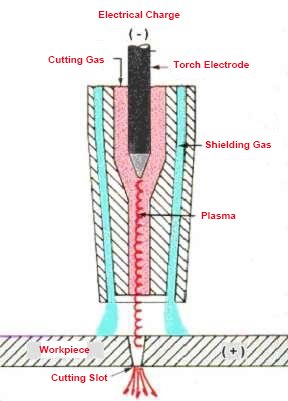

The plasma jet of high temperature and high speed is blown out from the nozzle.

Normal table with collect drawer or water table.

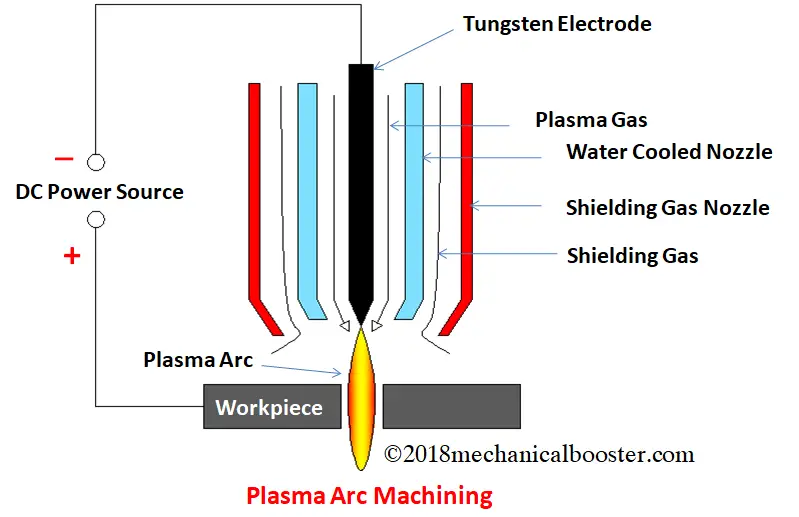

Is passed through a small chamber in which a high frequency spark arc is maintained between the tungsten electrode cathode and the copper nozzle.

Adding heat to material causes the molecules in it to vibrate or move more quickly.

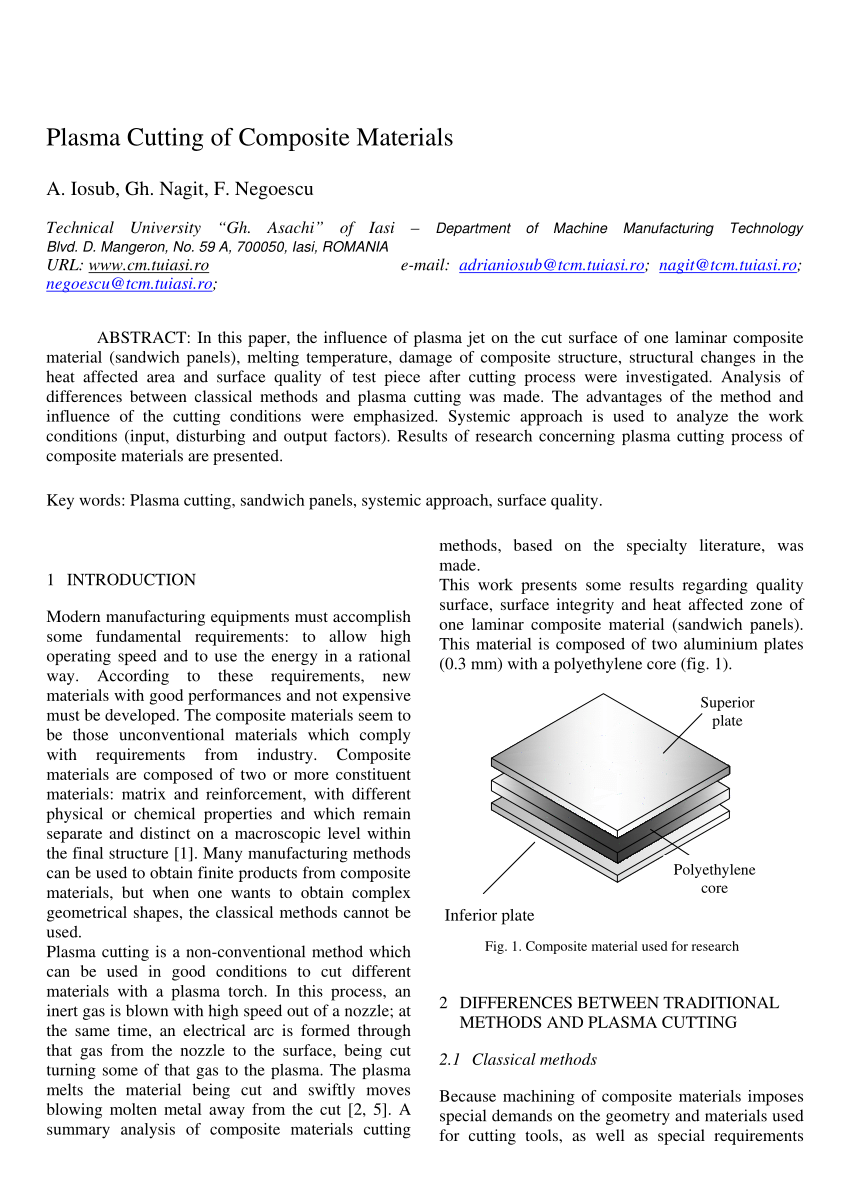

The plasma arc cutting process is illustrated in fig.

This high temperature plasma jet melts the material of the workpiece.

This is a cutting system utilizing heat generated by arc discharge between the cutting object material and the electrode inside the torch.

And the cutting object material is fused to be cut.

This increases the temperature and velocity of the plasma emanating from the nozzle.

Although it can be 40 for handhelds which means the following.

Working principle of pam.

4 minutes of plasma cutting is working and 6 minutes is necessary for it to cool down.

The so called pv duration of inclusion is 100.

Principle of plasma cutting means to focus a lot of.

More space is preferable for loading metal plate especially when you load by forklift.

Machine plasma cutting machines use water for cooling so the whole shift can work without interruption.

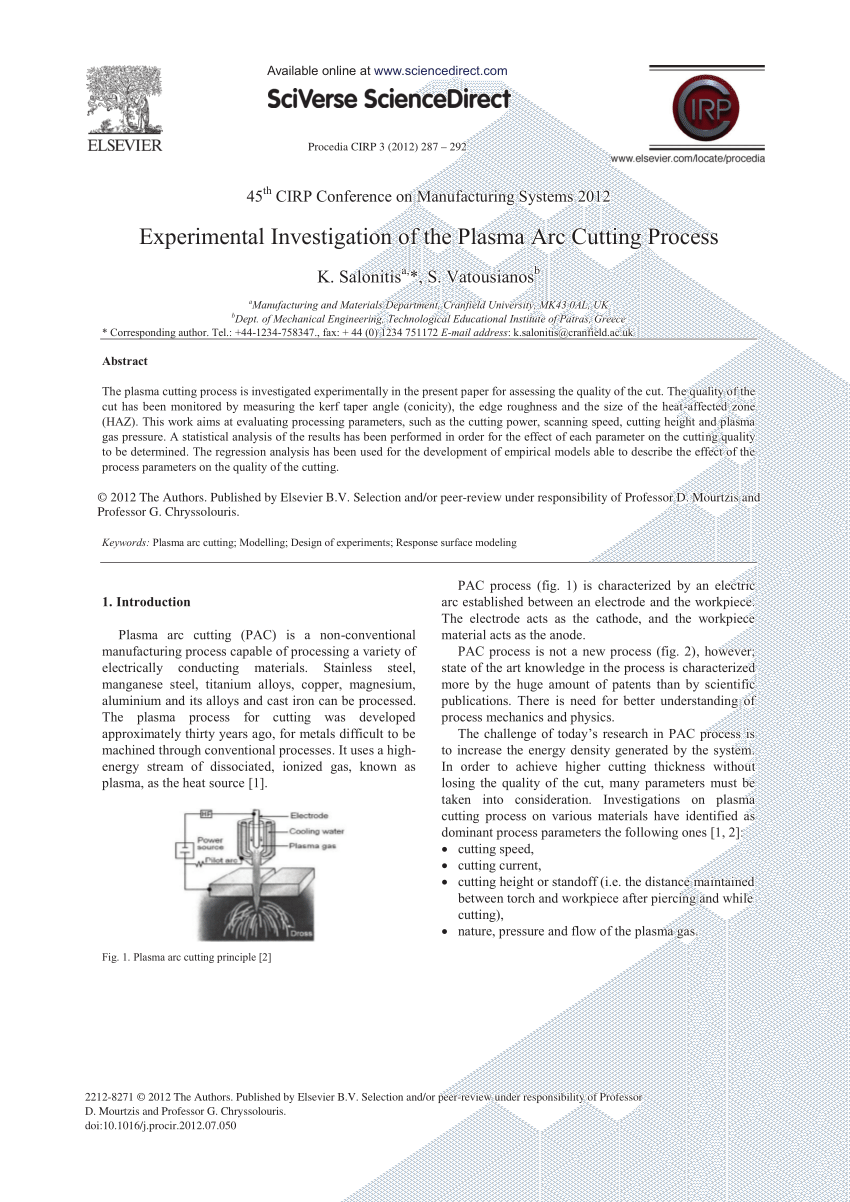

Working principle of plasma arc machining the principle of plasma arc machining is shown in the figure.

The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore copper nozzle.

In a plasma torch known as the gun or plasmatron a volume of gas such as h2 n2 02 etc.

Plasma arc machining working principle diagram process details of pam.

Atmospheric conditions from the working zone etc.

Plasmorez with own hands.

A plasma is a state of matter like a solid liquid or gas.

Describe the plasma arc cutting process and its applications in the pipefitting trade identify the different components of plasma arc cutting equipment and ppe required for it s use list the characteristics and hazards associated with plasma cutting safely set up the equipment adjust air pressure and current to correct.

When a solid is heated the molecules start to vibrate more vigorously.

In the plasma arc machining process the material is removed by directing a high velocity jet of high temperature 11000 c to 28 000 c ionized gas on the workpiece.