Chromium metal is added to alloy steel to increase.

Plasma cutting stainless steel hazards.

This document does not deal with uv hazards.

It is usually produced by an industrial process.

13 plasma cutting generates fume gases noise and ultraviolet radiation uv hazards.

The federal occupational safety and health administration changed its notification requirements in.

The resulting dross that hardens on the bottom of the plate is very easy to remove and often does not require secondary operations like grinding.

Iron steel cast iron and copper.

The chromium content in stainless steel and the health risks associated with overexposure to chromium make periodic air monitoring in the welder s breathing zone a.

A new rule aims to give workers more information about exposure to hexavalent chromium a carcinogen released when stainless steel is welded cut with a plasma torch or cast.

It is also a hobby for many metal cutting enthusiasts.

This is especially true for thicker stainless steel plates where plasma cutting is almost universally considered the best solution.

In addition it targets the respiratory system kidneys liver skin and eyes.

Will a plasma cutter cut stainless steel considering the fact that one particular within the positive aspects making use of a plasma cutter will be the fact that you could cut stainless steel metal quickly and completely it appears reasonable get started on your personal voyage directly into the realm of slicing by using stainless steel.

Cr vi is known to cause cancer.

One danger of cutting galvanized steel is metal fume fever a condition caused by the released zinc fumes.

Cutting of stainless steel is potentially the most hazardous as the fumes will contain chromium and nickel.

Thermit welding uses a chemical reaction to produce intense heat instead of using gas fuel or electric current.

14 the nature of fume depends upon the metal being cut and upon any coatings.

Oxy fuel and plasma cutting along with brazing are related to welding as they all involve the.

Plasma arc cutting hazards.

Pressure welding uses heat along with impact type pressure to join the pieces.

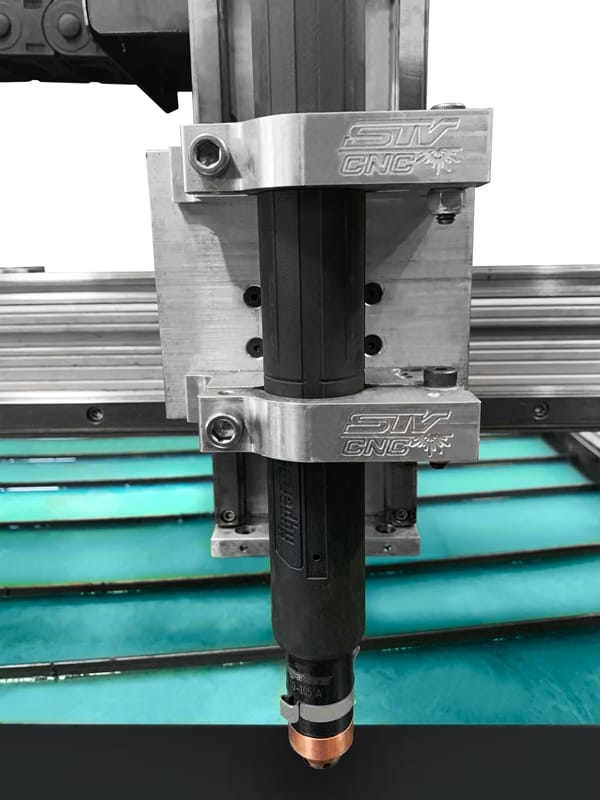

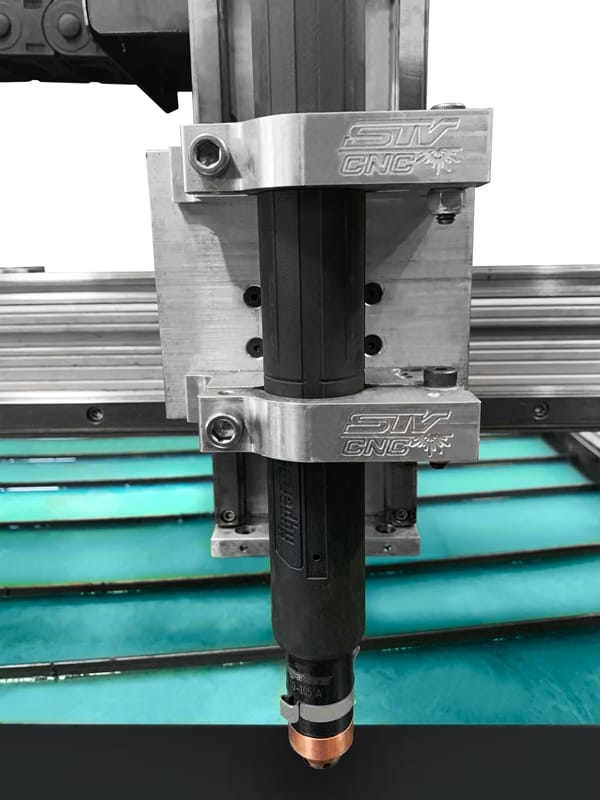

Plasma cutting is one of the most popular processes for cutting steel and other metals in many manufacturing shops.

An additional challenge plasma cutting of stainless steel presents is molten material viscosity.

Precision plasma can pierce and cut stainless steel up to around 40mm and high amperage plasma systems can pierce and cut stainless steel up to around 100mm.

The condition usually only lasts a single day according to the occupational safety and health administration with workers most susceptible after several days away from the work environment.

Hexavalent chromium cr vi is one of the valence states 6 of the element chromium.

When mild steel is cut with o2 air the viscosity of the molten material is much lower than when cutting stainless steel.

Because it s a thermal cutting process it produces plasma cutting smoke.

Handling dross and piercing.